Electrically heated fryer

The most easy-to-operate electric fryer with the updated technology of alpha coated electric heater(Patented in Japan). Thanks to the alpha element disintegrating water in the oil, oil can be kept clean, thus ensuring the optimum frying quality. The special electric heaters have very thin structures, ensuring the heat transfer balance between left and right in the vessel. The heaters also radiate infra-red ray so that the core and the surface of the products will be cooked evenly.

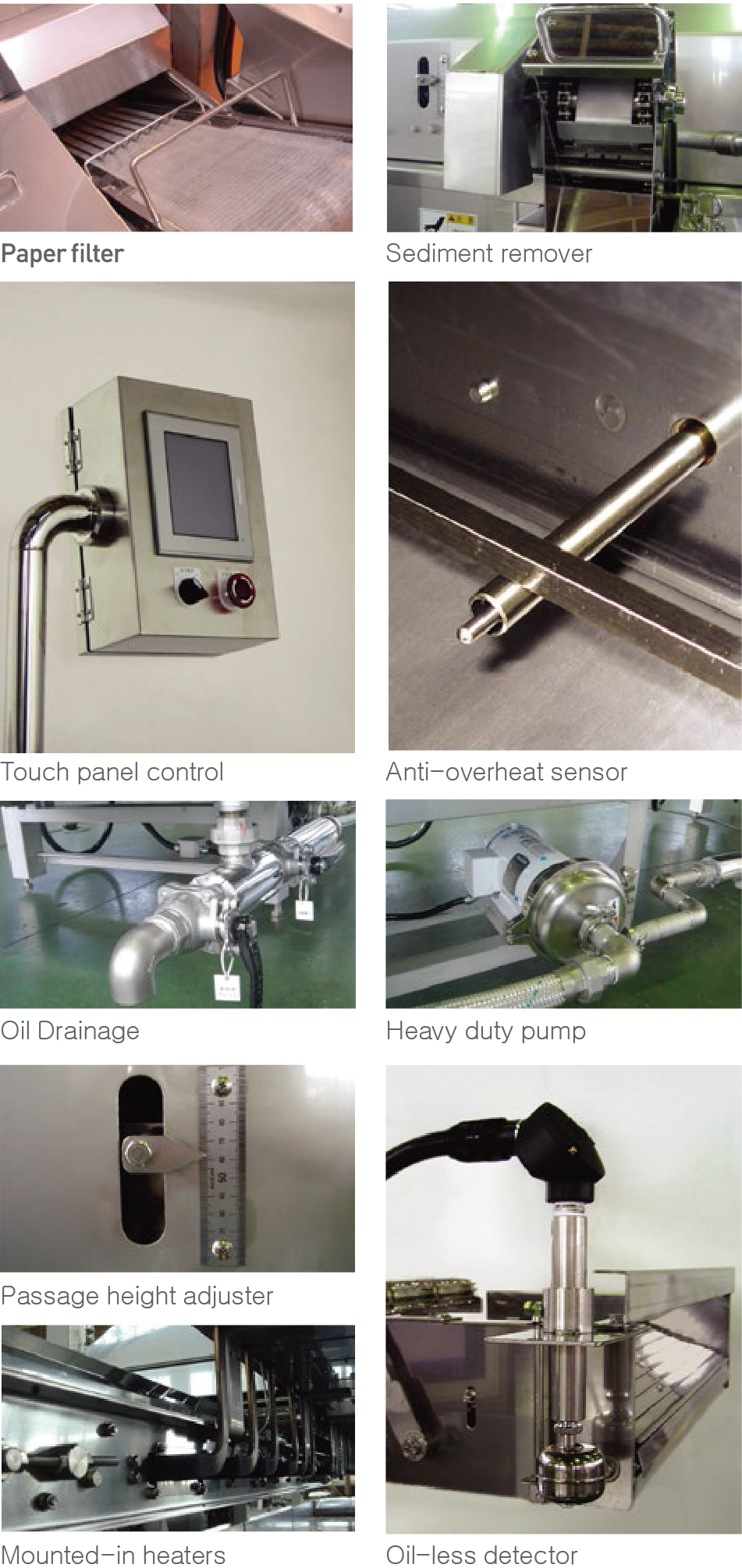

The system working is motorized. All the components such as hood, conveyors, heaters are lifted up and down by electric motor systems, giving operators a good access condition for cleaning and maintenance.

For battered products, the special caterpillar conveyor substitute itself for the conventional Teflon conveyor which requires periodical replacement at higher costs.

2 sediment removal conveyors are effectively taking most of the impurities out of the system. Paper filter or screen conveyor will be installed on demand from the user. Our unique vertical outside filtration unit ADF(See the page 19) is recommended optionally for entire oil filtering process even for such powder-coated product as pop-corn chicken, etc.

All the surfaces of the system are insulated and finished with welltreated stainless steel covers. Oil can be circulated on customer’s request.

- Standardized caterpillar conveyor dealing with wide range of product kinds.

- Low watt density of heaters keeps the temp of heater surface lower than 180℃ minimizing oil deterioration.

- Alpha particles are radiated into oil for keeping oil lifetime longer.

- Less oil volume and higher oil turn-over rate.